At a time when the transition to alternative energies for the mobilization of passengers in public transport is at the highest point of government agendas, many public and private operators are concerned about the costs of this process.

That is where Kleanbus appears, a modular platform to convert Diesel buses into fully electric vehicles. According to the company, the conversion costs a fifth of a new electric bus and is relatively simple to carry out.

According to company spokespersons, this solution is the fastest and most profitable for the transition of the UK bus fleet to the Zero Emissions model. With close to 35,000 diesel buses in circulation, Kleanbus founder Joe Tighe says the country faces "a big challenge to rapidly decarbonize the transport sector" and, according to him, is not moving fast enough on this task. .

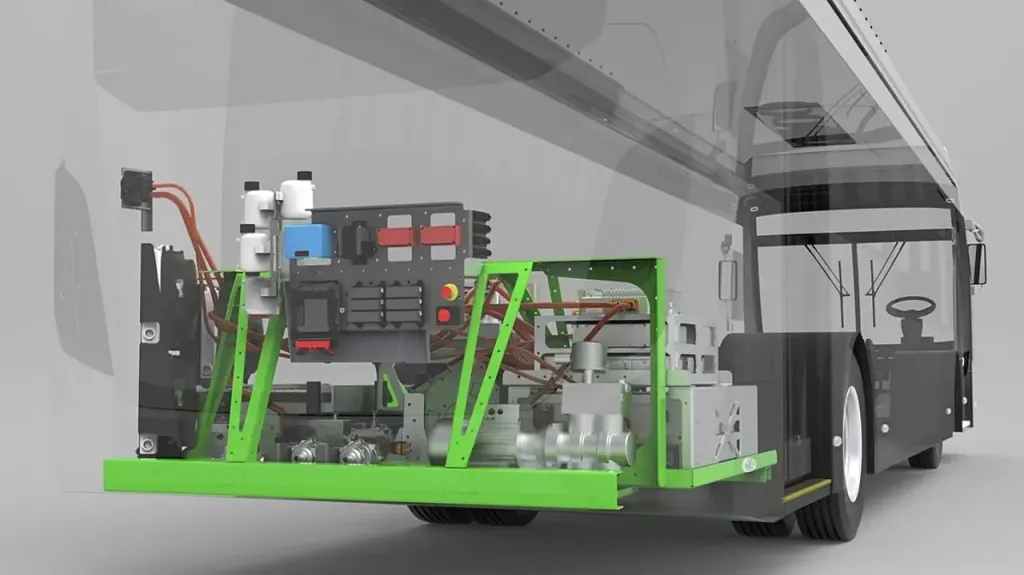

The components of the electric kinematic chain (motors, batteries, inverters, etc.) are manufactured by top-tier suppliers, although the brands of the components were not reported in detail, however, the management software is developed by Kleanbus. . The British company says that its platform is adaptable to different bus models in order to take advantage of the variety of batteries and engines available on the market, depending on customer needs.

No technical details have been announced, except for one with an eye toward sustainability. Kleanbus will use electric motors without permanent magnets, which do not need rare earths. This makes it possible to reduce, on the one hand, dependence on very expensive materials such as neodymium and dysprosium, and on the other, it reduces the environmental impact of obtaining these minerals.

At its facilities in the east of England, Kleanbus receives the diesel buses, does a complete overhaul and removes all the mechanical components associated with the engine, including the gearbox, radiator and electrical system. Next, a three-dimensional scan of the opening of the bus to be converted is carried out and the digital prototypes are created with the new platform and the components of the new electric drive. Once installed, quality tests and final certification are carried out before delivery to the customer.

Kleanbus says that once the electric drivetrain has been designed and tested, it takes less than two weeks to complete a bus conversion. The company can convert any bus, be it single or double decker (widely used in London). The price of the transformation is one fifth of a new electric bus. To this we must add that the operating costs are also much lower, approximately one third of the costs of a conventional Diesel bus. Kleanbus offers fleet operators to rent the battery or buy it together with the rest of the vehicle (or retrofit).